The different layers of our thermal paper

At Ricoh, our thermal papers consists of a base paper coated with four different chemical layers on the front that create their unique thermal and protection properties. The following is an overview of these layers. Please note that this overview does not include information on the adhesive layer or the Silicon release liner.

Base Paper

This layer is specifically designed for aesthetic and technical properties alike. Aesthetic properties include color, whiteness, brightness, and opacity. Technical properties include thickness, basis weight, tear strength, tensile strength, stiffness, and coating compatibility.

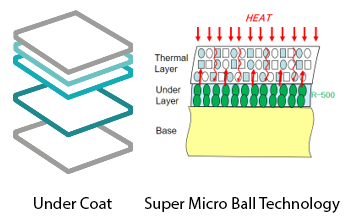

Under Layer

The Under layer has two main functions:

1. It smooths out the porous surfaces of the base paper to increase contact area with the thermal print head

2. It utilizes Ricoh's Super Micro Ball technology to retain more heat to drive the dye/ developer reaction forward with more efficiency.

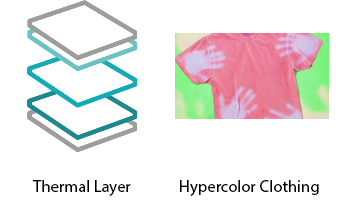

Thermal Layer

This layer contains a blend of the leuco dye* and the developer** which allows for color forming once heat is applied.

*Leuco Dyes are chemicals which can switch between colorless and colored forms. A popular example is hypercolor clothing which uses a leuco dye to change color with heat.

**Developers are organic acids that promote the color forming reaction when melted together with a leuco dye.

1st Overcoat AKA Barrier Layer

The 1st Overcoat or Barrier Layer is a transparent polymer layer designed to protect the thermal coat from premature darkening due to abrasions and environmental weathering. Without this layer, our labels would be much more prone to scratches or marks that may interfere with the scanning of barcodes.

2nd Overcoat AKA Matching Layer

The 2nd Overcoat or Matching Layer is a polymer layer that contains a filler designed to prolong the lifespan of thermal printers. Without this layer, our end users’ print heads would wear out much more quickly.